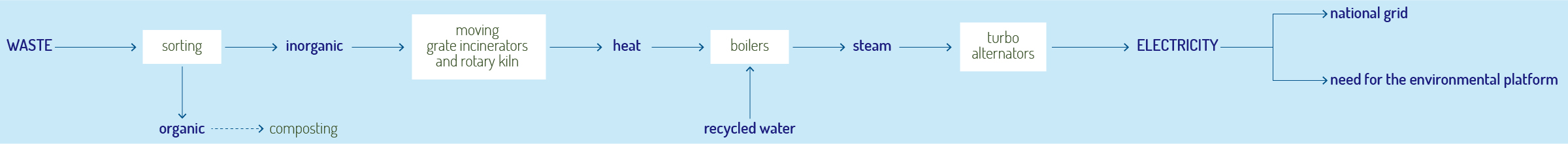

The dried fraction of municipal and industrial solid waste – often destined for landfill – is transformed into electricity through the waste-to-energy process, making the entire Environmental Platform energy self-sufficient and enabling the feeding of surplus energy into the national grid.

The electricity generation cycle

CACIP’s dedication to the territory and the community and to protecting the environment has also led to the revamping of two of the three lines of the Consortium’s waste-to-energy plant in Macchiareddu.

This upgrade aims to reduce emissions in line with the targets of the Integrated Environmental Authorization and to increase the plant’s incineration and electricity generation capacity.

Self-sufficiency and sustainability

The main features of the two new waste-to-energy lines, each with a nominal heat output of 23.7 MW and with a water- and air-cooled grate incineration system, are:

- combined heat and power generation through a new turbine, replacing one of the two existing ones and the upgrading of the remaining turbine, with electricity output of 16 MW.

- the installation of a new combustion fume treatment system comprising a bag filter for removing coarse solid particulates, followed by a second bag filter preceded by the injection of sodium bicarbonate and activated carbon as chemical reagents, to remove fine solid particulates and acid pollutants, and a catalytic system for the removal of NOx and residual micro-pollutants.

The work to achieve these objectives is quite complex and includes the removal of lines “A” and “B” of the existing plant at Macchiareddu – after disconnecting them from the plant’s other lines and other parts of the structure, to which lines A and B are functionally connected. This involves the installation of new technical systems and structural work on the building including constructing pier and beam foundations, and reinforced concrete and metal above-ground structures replacing or supplementing the existing structures.

All the works will be carried without stopping the plant; waste-to-energy line “C” (which will not be revamped) and line “B” will remain in operation for the entire period of work on line “A”. Work on line “B” will only start after the new line “A” has been tested and started-up. The sequence of revamping activities will be scheduled to ensure that the existing treatment lines continue operating as usual throughout the period of works.

Municipal and industrial solid waste treatment cycle

The municipal and industrial solid waste delivered to the Environmental Platform in Macchiareddu, managed by the subsidiary Tecnocasic SpA, and destined for the waste-to-energy plants, follow two different processing paths.

Municipal solid waste is first passed through rotating screens to separate the organic fraction.

This is transferred to composting plants, while the dry fraction (paper, plastic, etc.), known as RDF (refuse-derived fuel), is destined for waste-to-energy processing.

The waste-to-energy plant can receive over 600 tons of municipal waste daily.

Solid industrial waste is sent directly to the waste-to-energy plant and is incinerated in a combustion line with a rotary kiln, capable of treating about 30,000 tons per year.

The thermal energy produced by waste-to-energy plants is converted into electricity.

The heat from the moving grate incinerators and the rotary kiln is conveyed to steam boilers that power two sets of turbo alternators capable of producing all the electricity needed to power the Environmental Platform and of supplying over 40 million KWh to the national grid.

The residual ash from waste-to-energy processing is transferred to the chemical-physical treatment plant, where it is inertised and sent to controlled landfills.

Visit the waste-to-energy plants